Just like other industries, the RV industry is constantly innovating and coming up with new materials and construction techniques.

One of the most significant innovations in RV construction in recent years though has been the development and use of Azdel.

But what exactly is Azdel, and how does it make RVs better?

These are just a few of the questions will be exploring in this blog post that’s all about Azdel.

So if you’ve ever been curious about Azdel, make sure to keep reading.

As we’ll be answering some of the most common questions about Azdel, starting with what it is exactly.

What is Azdel?

Azdel is a green-based composite panel that can be used for RV exterior and interior sidewalls, ceilings, and roofs.

The product was developed and designed to be used as an alternative to wood-based or luan plywood panels, which were the industry standard in RV construction for decades.

Azdel is generally considered a superior product compared to wood-based RV panels, due to its numerous benefits.

As Azdel offers superior insulation value, improved sound deadening, and lighter weight compared to wood, as well as excellent durability and strength.

What is Azdel Made From and How is it Used in RV Construction?

Azdel is made from a patented blend of polypropylene and fiberglass to create a strong, lightweight, temperature-resistant, and environmentally-friendly RV panel.

As Azdel composites do not grow mold, mildew, or emit toxic fumes, nor do they use formaldehyde.

Plus, Azdel also has low VOCs or Volatile Organic Compounds, which are chemicals that can off-gas into the air we breathe.

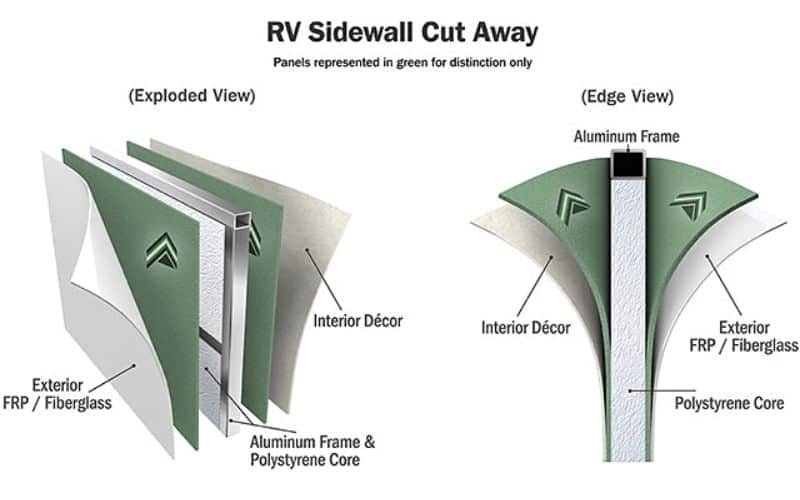

Panels made from Azdel are used as a replacement to luan plywood panels in RV construction and provide one of the many layers that go into RV walls and roofs.

As the typical RV wall or roof is comprised of multiple layers of material.

Including such materials as fiberglass, aluminum framing, batt or foam insulation, and interior decor panels.

As seen in the above RV sidewall cross-section, which denotes the Azdel panels in green.

Is Azdel Better than Luan?

Azdel is generally considered better than luan for several reasons, including better insulating capability, improved sound deadening, lighter weight, and better durability.

Better Insulating Capability

Azdel has twice the insulating capability or more compared to luan depending on thickness.

As Azdel and luan panels are offered in various thicknesses, with thicker options offering more insulation or R-value.

For example, Azdel panels are commonly produced in thicknesses ranging from roughly 1/10 to 1/4 inch, while luan panels are widely produced in thicknesses ranging from 1/4 to 3/4 inch.

Regardless of thickness though, Azdel generally always provides a better R-value.

As Azdel panels generally provide an R-value of around 4, while luan panels generally only provide an R-value of 2 or less.

Improved Sound Deadening

Azdel also provides improved sound deadening compared to luan as well.

Due to the fact that Azdel panels are made from polypropylene and fiberglass, both of which absorb sound better than wood-based materials.

Lighter Weight

Another advantage that Azdel has over luan is that it’s much lighter.

As Azdel weighs about half as much as luan does.

Making Azdel an ideal choice in RV construction, as lighter materials help to reduce the total weight of the RV and improve fuel efficiency.

Better Durability

Finally, Azdel is also more durable compared to luan, thanks to its non-wood-based polypropylene/fiberglass makeup.

Which helps to improve the longevity and durability of the RV.

As RVs that use Azdel panels generally hold up better over time and have fewer maintenance issues compared to those that use luan panels.

Also, the use of Azdel eliminates the need for wood-based products in the RV’s walls and roof.

Which greatly reduces the risk of delamination and pest issues.

As Azdel will not expand or become swollen if it gets wet like luan, in the event of a leak, which is a leading cause of delamination.

In addition, Azdel also eliminates the risk of pests like termites and other wood-boring insects.

What are the Disadvantages of Azdel?

The main disadvantage of Azdel is its cost, as Azdel is generally more expensive than luan or other wood-based materials.

Due to Azdel’s higher ingredient and specialized manufacturing costs.

Because of this, RVs that use Azdel tend to be more expensive compared to those that do not.

However, this added cost is usually offset over time by Azdel’s improved durability and performance.

As Azdel RV panels are more resistant to water damage and temperature fluctuations.

Allowing RVs that offer Azdel construction to provide a better long-term investment.

As Azdel RVs are less prone to costly repairs, such as delamination, which can provide considerable cost savings to the RV owner.

Beyond cost though, there are two other disadvantages of Azdel, including Azdel’s inferior bonding adhesion and poor screw retention compared to luan.

Which can make the manufacturing process more complicated as well as more costly for the RV manufacturer.

As the RV manufacturer must incorporate specialized processes and many layers of materials into their RV panels when using Azdel, to compensate for the inferior bonding and screw retention of the product.

However, both of these issues are really non-issues in today’s RV manufacturing process.

As there are tried and true methods that deal with both issues.

How Can You Tell If An RV Uses Azdel?

If you’re shopping for a new RV and want to make sure that it uses Azdel construction, one of the easiest ways to tell is to look for the Azdel sticker on the side of the RV, usually near the entry door.

As RV manufacturers will almost always place a sticker on the RV like the one above, to let customers know that Azdel construction was used, due to all the benefits of Azdel.

However, just because you don’t see an Azdel sticker that doesn’t mean that Azdel wasn’t used in the RV’s construction.

As the RV manufacturer may have chosen not to place stickers on the RV for a cleaner look or the sticker might have been removed for some reason.

So if you don’t see an Azdel sticker on the RV you can also check the RV manufacturer’s website or check with the RV dealer to find out whether Azdel was used in the RV’s construction.

It’s worth pointing out though that the use of Azdel can vary from one RV to the next, even if they both offer Azdel construction.

As some RV manufacturers use Azdel in all their RV panels, including the sidewalls, roofs, front caps, and back walls.

While other RV manufacturers only use Azdel on certain walls or panels.

So even if the RV manufacturer advertises the use of Azdel, it can be worth figuring out where or how much Azdel was used in the RV’s construction.

What RV Manufacturers Use Azdel?

Below is a list of RV manufacturers that use Azdel in the construction of their RVs in some capacity, listed in alphabetical order.

- Aliner

- Alliance

- ATC

- Braxton Creek

- Brinkley

- Coachmen

- Cruiser

- Dynamax

- East to West

- Ember

- Encore

- Entegra

- Flagstaff

- Forest River

- Gulfstream

- Heartland

- IBEX

- Jayco

- Kingdom Camping

- KZ RV

- Lance Camper

- Leisure Travel Vans

- Newmar

- Nexus

- No Boundaries

- nuCamp

- Palomino

- Phoenix USA

- Renegade

- Riverside

- Rockwood

- R-Pod

- Shasta

- Surveyor

- Tiffin

- Travel Lite

- Winnebago

- Work and Play

- Xtreme Outdoors

Does Lance Use Azdel?

Lance uses Azdel in both their travel trailer and truck camper lineups.

Which should come as no surprise.

As Lance is known for their premium materials and construction, which utilizes not only Azdel but also other class-leading manufacturing methods.

Including SolidWorks™ 3D design software, laser-guided cutting machines, LanceLock™, Euro-Ply™, and the removal of mercury and formaldehyde.

Does Winnebago Use Azdel?

Winnebago uses Azdel construction in both their motorhome and towable lineups.

Which include popular models, such as the Vista, the Minnie Winnie, the Hike, and the Micro Minnie.

It’s worth pointing out though that while all Winnebago branded RVs use Azdel, not all RVs produced under the umbrella of Winnebago Industries, which owns brands, such as Grand Design and Newmar do.

Why Does Grand Design Not Use Azdel?

Grand Design is one of the most well-respected RV brands out there, renowned for its build quality and premium RVs.

So it might come as a surprise to you that Grand Design does not use Azdel in its manufacturing process.

But why is this?

Well, there are many reasons you could point to.

The three most likely reasons though, why Grand Design doesn’t use Azdel, are cost, inferior bonding adhesion, and poor screw retention.

Starting first with cost.

Azdel costs considerably more compared to luan.

So any RV manufacturer still using luan over Azdel has substantial manufacturing cost savings.

However, I suspect in the case of Grand Design, it’s less about cost savings and more about design and production processes.

Leading us to the last two reasons why Grand Design likely uses luan over Azdel, which are poor bonding adhesion and screw retention of Azdel.

Because while Azdel excels at many things, including durability, insulation, and sound deading; bonding adhesion, and screw retention or not two of them.

As luan is superior at both bonding and screw retention compared to Azdel.

This means that Grand Design would have to completely change its design and production process to incorporate Azdel.

However, because Azdel has been around for the better part of 20 years, personally I would say this is a poor excuse not to make the transition to an obviously superior product.

Given the time span, Grand Design has had to transition.

When Did RV Manufacturers Start Using Azdel?

Azdel has been used in RV construction for almost 20 years now, with the first Azdel RV composite panels being produced in 2006.

Since then, Azdel has become a staple in the RV industry, as manufacturers look to create lighter, more durable, and better-insulated RVs.

Today, Azdel is used by many of the industry’s leading RV manufacturers, including Coachmen, East to West, Forest River, Gulfstream, Jayco, KZ RV, Lance, Palomino, and Winnebago.

And thanks to Azdel’s superior insulation, sound deadening, and strength-to-weight ratio, it’s no surprise that Azdel is quickly becoming the go-to material in RV wall, ceiling, and roof construction.

What are the Alternatives to Azdel?

As of right now there really are no good alternatives to Azdel that offer the same level of durability, strength, insulation, and weight reduction.

Because of this, the vast majority of RV manufacturers use Azdel composite panels at least somewhere in their RV construction.

However, it’s worth pointing out that some RV manufacturers, like Grand Design, continue to use luan instead of Azdel.

In addition, it’s also worth mentioning that other RV manufacturers like Keystone, have chosen to develop their own in-house alternative to Azdel, such as Keystone’s HYPERDECK.

Because HYPERDECK is exclusive to Keystone though, it doesn’t really offer a good alternative to Azdel.

Even if the product offers many of the same features and properties.

How Thick are Azdel Walls?

Azdel panels are only about 1/10 to 1/4 inch thick, depending on the application.

However, that doesn’t mean that this is how thick an Azdel wall is.

As Azdel panels only make up a portion of a standard RV wall, which includes multiple layers of material.

Including not only several layers of Azdel panels but also exterior fiberglass or aluminum siding, aluminum framing, batt or foam insulation, and interior decor panels.

Because of this, when all these materials are combined, the thickness of an average Azdel wall ranges from 2 to 2 and 1/2 inches thick.

Which is the same as a luan plywood wall, which is also about 2 to 2 and 1/2 inches thick.

Recent Posts

When cruising down the highway in your RV, the last thing you want is a tire blowout! Not only is it dangerous, but RV tire replacement isn't cheap, costing $200 to $300 per tire. The good news,...

Nothing ruins an RV adventure faster than a breakdown with no way to fix it. Because of this, every RVer should have a well-stocked RV tool kit for those unexpected roadside emergencies and campsite...